Cracks are among the most common and dangerous forms of damage in materials and structural components—if left unchecked—can lead to sudden and catastrophic failure.

In the maritime industry, one of the main objectives of underwater inspections are to identify the presence of any cracks, in order to address them immediately before further propagation can offer.

But why do cracks form in the first place? And once they appear, what’s the most effective way to stop them from getting worse?

Let’s explore the root causes of cracking and how a simple technique called drill stopping can be a surprisingly effective line of defense.

Crack found in a propeller blade

Crack found in rudder plate

Why Do Cracks Form in Materials?

Cracks form when the internal stresses in a material exceed its ability to withstand them. These stresses can come from many sources:

-

Excessive mechanical stress

When a material is loaded beyond its strength—whether in tension, compression, or shear—it can develop microscopic flaws that grow into visible cracks.

-

Fatigue (repeated loading)

Even when loads are within safe limits, repeated cycles of stress (such as vibration or bending) can cause fatigue cracks to initiate and grow slowly over time.

Crack found in rudder blade

-

Thermal cycling

Materials expand and contract with temperature changes. Over time, this can induce internal stresses, especially when heating and cooling are rapid or uneven, leading to thermal fatigue cracks.

-

Manufacturing flaws

Defects like voids, inclusions, or welding errors can serve as crack initiation sites, especially under stress or in harsh environments.

-

Corrosion and environmental effects

Stress corrosion cracking, hydrogen embrittlement, or moisture absorption (in polymers) can weaken a material at the microscopic level, making it more prone to cracking.

Why Cracks Are Dangerous

Cracks are not just cosmetic. They act as stress concentrators—meaning the stress around the tip of a crack can be many times higher than the surrounding area. Once a crack reaches a critical length, it can rapidly propagate, leading to sudden and often catastrophic failure.

That’s why early detection and immediate action are critical.

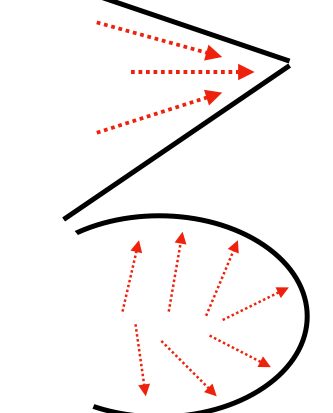

Stress concentrations at a crack and after drill stopping

Drill Stopping – A Simple Yet Effective Crack Arrest Method

One of the most widely used techniques for dealing with existing cracks is drill stopping—also known as stop drilling.

What is drill stopping?

Drill stopping involves drilling a small, round hole at the very tip of a crack to prevent it from growing further.

This may sound counterintuitive—why would you drill into an already damaged part? But it’s backed by solid mechanics.

Diver performing drill stopping

How it works

- A crack has a sharp tip, which causes extremely high stress concentration.

- Drilling a hole removes the sharp tip and replaces it with a rounded geometry.

- The hole reduces the stress intensity factor at the crack front.

- As a result, the crack is less likely to propagate further.

Benefits of drill stopping

- Quick and cost-effective fix for managing cracks

- Requires only basic tools (drill and bit)

- Extends the life of components and allows time for maintenance, or replacements to be made

- Can be done in the field with minimal downtime

Pro tips

- It’s important to correctly identify the extent of all the cracks and indications in the damaged areas

- Ensure the areas to be inspected are properly cleaned of any marine growth, corrosion and paint coating that could potentially obstruct the crack-like indications

- Prior to drilling, make sure to find the very end of all cracks, use Magnetic Particle Inspection or other NDT techniques if necessary

- After drill stopping, the holes and any drill cores should be closely examined to ensure the end of the crack was captured

Navigating Cleaner Seas: The Role of EGCS Systems on Commercial Vessels

Navigating Cleaner Seas: The Role of EGCS Systems on Commercial Vessels