The Persistent Need for Diver Intervention

Since modern seagoing commercial vessels are under constant pressure to keep their ships afloat and to avoid downtime and costly dry docking at all costs, performing routine maintenance and testing on a vessel’s internal plumbing often requires diver intervention.

Marine piping and plumbing systems form an integrated network of meticulously engineered components that work together to transport fluids and gases throughout the bowels of the vessel.

As you can imagine, there are plenty of onboard systems, water, oil, ballast, sewage, etc., All of which are fitted with their own set of valves, pipes, pumps, and tanks, depending on their function.

These systems are crucial to maintaining normal vessel operations. For example, seawater intakes supply cooling water to the main engines, without which, the engine would overheat and seize.

The systems can be simplified as, intakes (drawing fluids or gases into the vessel), discharges (drawing fluids or gases away from the vessel) ,or internal (transporting within the vessel itself).

From an underwater standpoint, intakes and discharges either start or end with, a through-hull penetration.

This penetration of the hull plating creates an area of concern, and where diving intervention is often required. As these openings are located below sea level, they offer a direct passage for the open ocean to enter the vessel. Any failure of the outboard valves, or maintenance of these systems without proper chocking techniques, could be catastrophic.

Plugging, blanking, and sealing

Generally speaking, plugging and blanking techniques are utilized by divers as a method to arrest seawater ingress into a vessel. This allows internal vessel operations to be conducted in a dry, safe environment.

The benefits of carrying out their operations in-water are astoundingly cost-effective as fabrication, installation, and removal are generally quick and can be completed with minimal equipment.

Depending on the scope-of-work, underwater blanking operations may be a definite necessity, a safety redundancy, or a Class requirement.

Safety

It is imperative that proper safety procedures are in place prior to any subsea blanking operations.

Further to the aforementioned concerns of water ingress into the vessel, submerged inlets are subject to suction pressures known as “Delta P” and remain a significant hazard to entrapping divers.

Thai Subsea Services holds Class approved underwater blanking, plugging, and sealing procedures and always enforces the use of safe job practices.

Operations

Intakes are generally located within the sea chests; their chambers are fitted with gratings or strainers, which help to prevent foreign debris from passing into the vessel.

Sea chest blanking is normally carried out by installing cover plates over the external gratings and drain holes. The internal chamber is then dewatered internally.

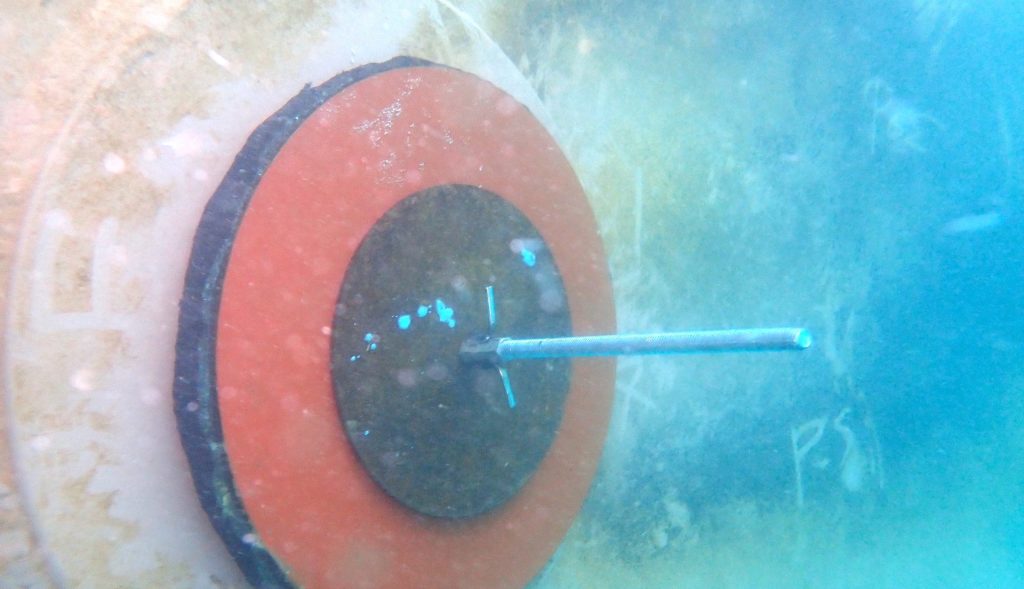

Discharges tend to be clustered in the engine room compartment, or at other locations of the vessel’s hull which are deemed necessary by the systems they support. Discharge plugging is normally carried out by inserting a pliable bung, or for larger diameters, fastening a plate over the external discharge opening.

|

|

|

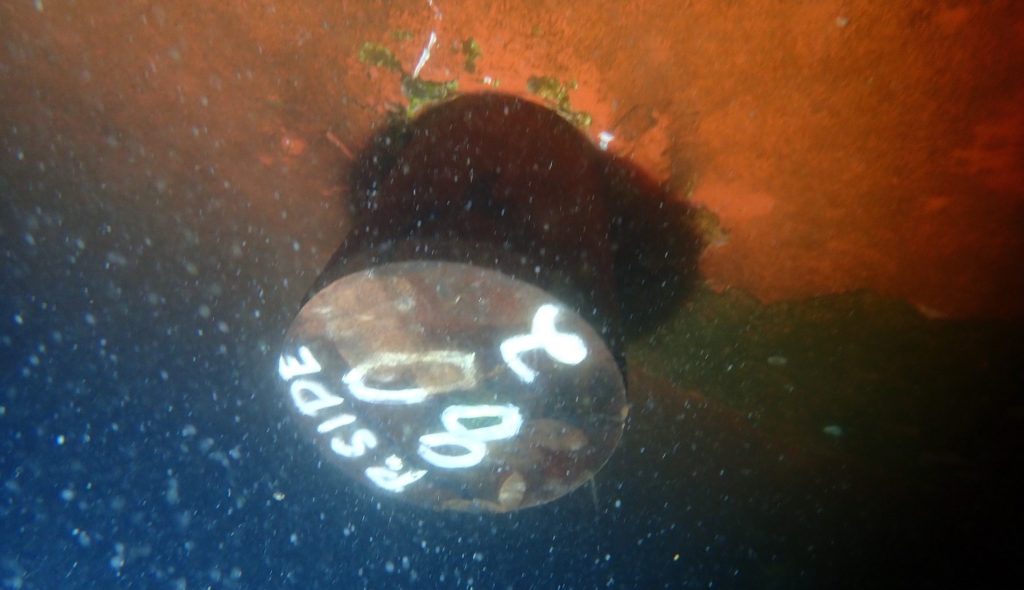

It is also important to mention the role of drain ports. While, not mechanically operated, drain ports can be fitted with plugs that are intended to be opened during dry-docking to empty or dewater their contents by use of gravity. These plugs can get damaged during their service life and may require sealing before the vessel’s next voyage.

Thai Subsea Services Ltd., carries a wide range of stock blanks, plugs, and cofferdams suitable to be deployed in any scenario.

In the event of odd sizes or complex geometries, we have the capacity to manufacture bespoke blanking equipment on our premises. All of our equipment is meticulously checked before deployment to the job.

Contact us for your free quote today