A propeller, known as a ‘screw’ for its appearance is a fan-like piece of machinery attached to the stern of a ship. They come in many varieties and designs, they can be left-hand turning or right-hand turning, they are fitted in pairs or in threes and may be covered in shrouds and nozzles. However, their main function is the same – to propeller the ship!

Typically made from nickel-aluminum-bronze alloys, a propeller, or ‘prop’ is generally located at the stern of the vessel and attached to a rotating hub at the end of a shaft that is driven by the engine of a ship. These metals and their alloys are ten to fifteen percent lighter than steel and are impervious to corrosion. However, some propellers, particularly ice-class vessels, can be composed of much harder, stainless steel alloys.

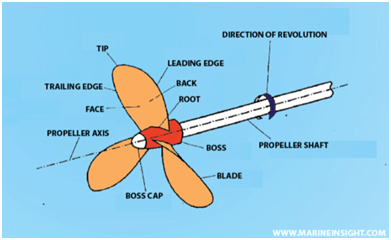

Understanding the geometrical construction and functioning of a propeller is imperative to maintain its efficiency.

In this blog, we will discuss propellers, their types, and common issues with solutions in detail. So let’s get started.

How Does a Marine Propeller Work?

Propellers are the most complicated, and thus, most important piece of machinery on any given ship.

Generally speaking, the pitch of the propeller dictates the ship’s forward movement. Therefore, a controllable-pitch prop would give the vessel a greater range of propulsion over a fixed-pitched one. Also, in theory, the more blades a propeller has, the more propulsion can be achieved.

The physics of a working marine propeller is akin to that of an airplane wing in flight, however, its operation is more complicated given the non-linear behavior of water. With every rotation of the propeller, there is a never-ending equilibrium power struggle between the suction face (negative) and pressure face (positive) of the blades which further promotes or demotes blade propulsion.

This an oversimplification of course, as there are other factors at play:

- Skew (The angle of the blade to the hub)

- Camber (The amount of ‘cupping’ of the blades),

- Rake (The ‘tilt’ of a blade forward or aft)

- Size to weight ratio

Conversely, there are many factors that restrict the efficiency of a propeller, known as ‘slippage’. These could be either inherited/external factors from the initial vessel build or from natural causes, or in-service defects:

Inherited

- Excess weight on the vessel

- Poor design. Either of the ship, the propeller,or both

- Using the wrong propeller for the ship

- Sea and weather conditions. Winds, sea currents, etc.

In-Service

- Deflections or ‘bends’ in the blades

- Excessive roughness caused by marine fouling or the like

- Cracks, cavitation, and pitting

- Foreign entanglement (Ropes, fishing nets, etc.)

- Damage to the stern seals

Maintenance of Propellers

Routine underwater maintenance, including frequent inspections, should be carried out by a professional service provider to help identify and quickly resolve any issues associated with the propeller and turning gear before they manifest into large, production-halting problems.

Underwater Propeller Maintenance could Include:

- Visual inspections

- Propeller shaft wear-down measurements

- Polishing of the propeller assembly to achieve maximum smoothness (Rubert ‘A’)

- Profile grinding and re-shaping of damaged propeller blades

- Drill-stopping micro-fractures in propeller blades to arrest crack propagation

- Straightening or cropping of completely damaged propeller blades

By hiring Thai Subsea Services Ltd. you can get your ship’s propellers inspected, polished,and repaired.They are the leading underwater ship specialists in Thailand and can perform a wide range of preventative and restorative propeller services to ensure your vessel’s smooth sailing.

Contact us today for more information.

Underwater Maintenance: What Your Vessel Needs

Underwater Maintenance: What Your Vessel Needs